how to make a kiln for lumber

This video is a compilation of my series on build my Kiln Chamber for the Woodmizer Dry Kiln. Methods to dry lumber a seasoned sawyer.

Help Needed With Diy Solar Kiln Control Fan Etc For Drying Wood Hearth Com Forums Home

Some potters advise on utilizing hearth bricks to construct a brick kiln.

. But now it needs to be dried. We show you how we built a budget dehumidifier wood drying kiln controlled by thermostat-----. Drying lumber requires raising the temperature to a degree that will release the water present in the lumber.

Heres how I built a quick and dirty solar kiln for less than 100Article. Although woodworkers have several different types of kilns to choose. To calculate the size of.

Kiln drying of lumber requires some attention. The following procedures apply to drying in a solar kiln. Place the heat source in the center of the kiln and then seal up the doors.

In feet of the wood stack times the thickness in feet of the stickers. Building a solar kiln is a great way to dry firewood quickly and efficiently. Fan needed in cfm multiply the number of sticker layers by the length.

The remaining width allows for a 36. Water content of the wood is converted into vapor by evaporation and discharged. The cost for the plans and materials list is 995 plus 495 SH.

For a detailed explanation of this process click on the link be. This would allow a stack of lumber four feet wide and 10 feet long. Kiln drying lumber is a simple cost effective method recommended for anyone who wants to increase profits by selling dried lumber.

You can use a wood stove a propane heater or even an electric heater. Now youre ready to start drying your lumber. A seasoned sawyer shares ideas of the.

Construct a floor frame. As you may expect this requires heat which is why it is called a kiln. It should have a tall rear wall a low front wall a sloped roof of clear polycarbonate usually.

Its beautiful to look at and a joy to. Kiln dried wood typically sells for a third more than. The lumber Ive dried during the two years that my solar kiln has been in operation has proved to be of outstanding quality and durability.

A conventional kiln uses steam flow into the kiln through pipes and radiates heat into the kilns atmosphere. How to Build Your Own Wood Drying Kiln Step 1. The kiln will need to be situated in an area that gets direct sunlight for most of the day.

For a single-stack kiln I recommend a minimum shed size of 8 x 12. You found some green wood for cheap or free great. To order call toll-free 1-888-636-4478.

Aug 08 2012 You can dry wood for Log Furniture and for normal wood. The kiln configuration and a drying schedule can be input and the code in the excel file will simulate drying lumber to the specified mc or for the specified time.

Drying Wood At Home The Wood Database

Home Made Vac Kiln In Drying And Processing

Kiln Dried Timber Devon Timber

Diy Dh Kiln Performance In Drying And Processing

Drying 650 Bf Of Walnut In A Homemade Kiln R Woodworking

How To Kiln Dry Firewood 10 Steps With Pictures Wikihow

Solar Kiln Plans Oregon Wood Innovation Center

How To Kiln Dry Wood Wood Drying Kiln Guide

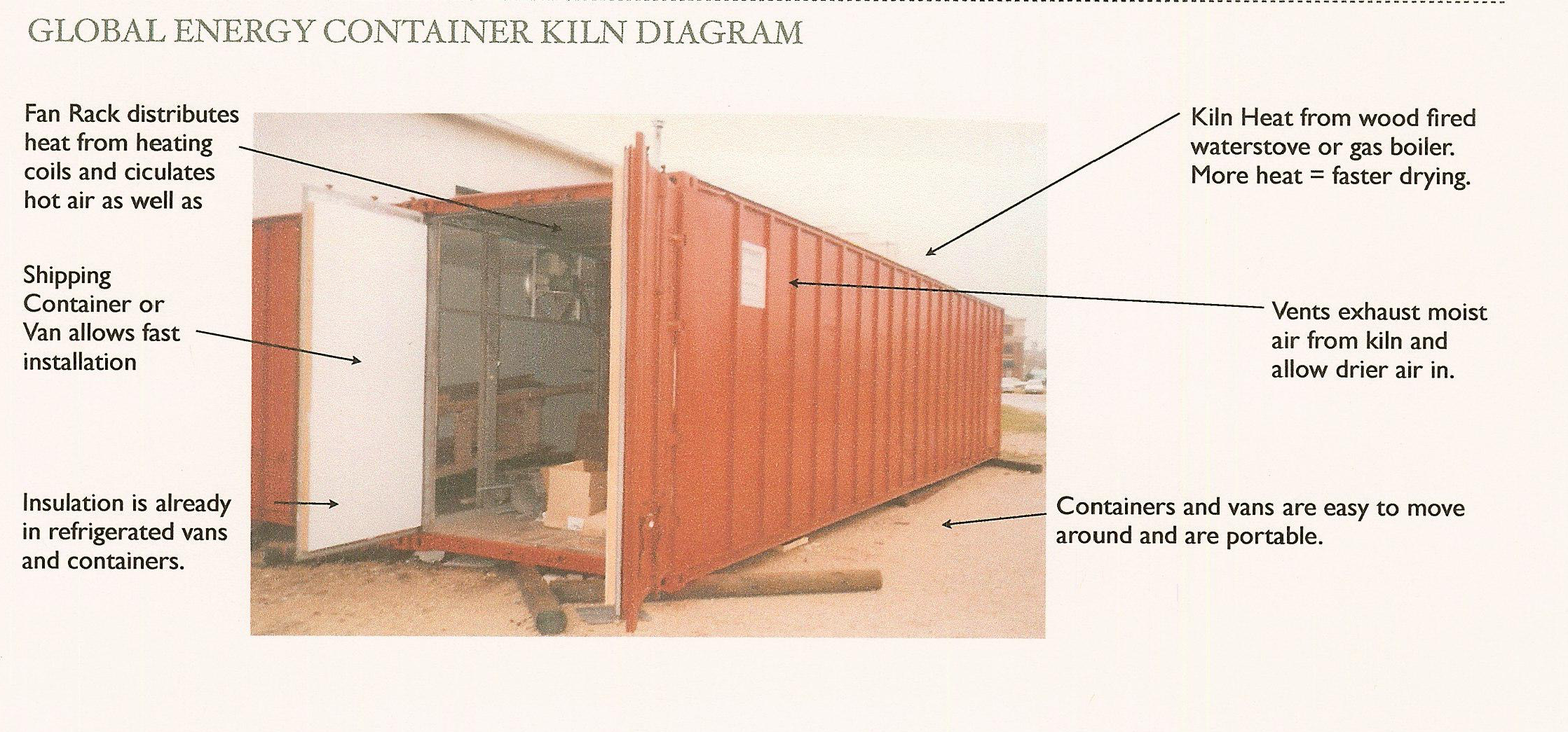

Shipping Container Lumber Dry Kilns By Global Energy

How To Kiln Dry Wood 7 Ways Mymydiy Inspiring Diy Projects

Sauno Wood Drying Kilns By Logosol Wood Processing

Container Kilns Packages Nyle Systems Brewer Maine

How To Build A Lumber Kiln The Complete Build Youtube

Building A Solar Wood Drying Kiln Grit Wood Kiln Solar Kiln Wood Shed

Vacuum Drying Kiln To Wood Technology Center Of Excellence Northcentral Technical College

Why How To Build A Wood Kiln Youtube

Buying Live Edge How Long Does It Take To Produce A Quality Live Edge Slab The Wood Cycle Of Wisconsin

An Experienced Wood Firer Shares Kiln Plans For A Small Instructional Wood Kiln